Understanding Structural Steel Fabrication

What is Structural Steel Fabrication?

Structural steel fabrication is the intricate process of transforming raw steel into specialized components that are essential for construction. This transformation involves a series of methods, including cutting, bending, and assembling various steel elements into final products tailored to meet specific project requirements. The resulting fabricated steel pieces serve as the backbone for buildings, bridges, and various infrastructures, ensuring structural integrity and durability. For a more comprehensive insight into structural steel fabrication, one must consider its extensive applications across various sectors.

Importance of Structural Steel

Structural steel plays a pivotal role in modern construction due to its strength, versatility, and adaptability. It is widely recognized for its remarkable load-bearing capacity, making it ideal for high-rise buildings and large-span structures. The inherent properties of steel, including its resistance to environmental impacts and its excellent performance under stress, position structural steel as a preferred choice among architects and engineers. Furthermore, the flexibility of design allows for innovative architectural solutions that can elevate the aesthetics of any construction project.

Types of Structural Steel Components

The landscape of structural steel fabrication includes a variety of components, each tailored for distinct roles in construction projects. Key types include:

- Beams: Horizontal supports that bear loads from above.

- Columns: Vertical structures that provide stability and support to the beams.

- Trusses: Frameworks designed to distribute weight effectively and reduce material usage.

- Plates: Flat steel components used in various applications, including flooring and walls.

- Angles: L-shaped bars used for structural support in many applications.

The Structural Steel Fabrication Process

Initial Design and Planning

The first step in the structural steel fabrication process is meticulous design and planning. This phase involves collaboration between architects, engineers, and fabrication specialists to ensure that the designs meet safety standards, aesthetic values, and functional requirements. Advanced software tools facilitate the generation of precise 3D models that outline dimensions and material specifications. These models assist in visualizing the final product and optimizing material usage while providing a detailed roadmap for subsequent fabrication stages.

Material Selection and Cutting Techniques

Choosing the right materials is critical. The selection process considers factors such as load requirements, environmental impact, and corrosion resistance. Once the materials are selected, various cutting techniques can be employed, including:

- Laser Cutting: Precision cutting with a laser for intricate designs.

- Plasma Cutting: Effective for thicker steel, using an electrically conductive gas.

- Waterjet Cutting: Utilizes high-pressure water mixed with abrasives for clean cuts.

- Band Sawing: Ideal for straight cuts in smaller projects.

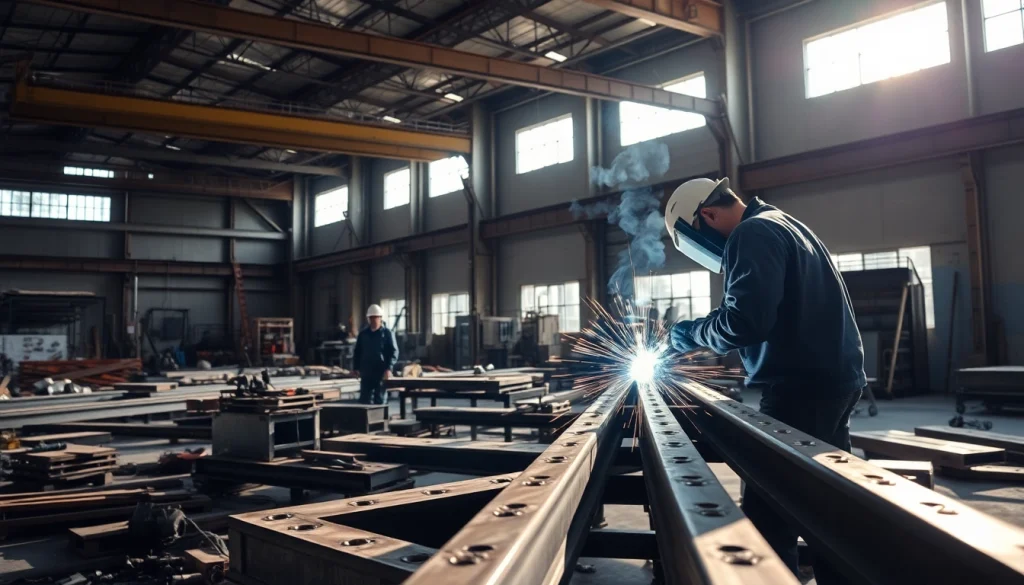

Welding, Assembly, and Finishing

Following cutting, the components undergo welding to assemble them into frames or structures. Qualified welders employ various techniques, ensuring strong joints that withstand the stresses imposed on the structure. Assembly may also involve bolting or riveting, depending on the specific requirements of the project. Finishing processes, such as painting and galvanization, ensure protection against corrosion and enhance the visual appeal of the fabricated components.

Best Practices in Structural Steel Fabrication

Quality Control Measures

Implementing stringent quality control measures is crucial in structural steel fabrication. Regular inspections, testing of materials, and monitoring of fabrication processes help ensure product integrity. Adhering to standards set by organizations such as AISC (American Institute of Steel Construction) and ISO (International Organization for Standardization) provides a framework for maintaining high-quality outputs.

Safety Protocols in Fabrication

Worker safety is paramount in any fabrication facility. Establishing comprehensive safety protocols, including the use of personal protective equipment (PPE) and regular safety training sessions, can significantly reduce occupational hazards. Additionally, machinery must undergo routine maintenance to prevent malfunctions and ensure a safe working environment.

Maintenance of Equipment

Regular maintenance of fabrication equipment is vital for operational efficiency and safety. Scheduled inspections, lubrication of moving parts, and timely repairs minimize downtime and enhance productivity. Keeping equipment in optimal condition prevents costly delays and ensures the quality of fabricated steel products.

Common Challenges in Structural Steel Fabrication

Material Costs Fluctuation

Fluctuating material costs pose significant challenges in structural steel fabrication. Factors such as market demand, availability of raw materials, and geopolitical issues can lead to price instability. Fabricators must adopt strategic procurement practices, negotiate long-term contracts, and explore alternative material options to mitigate these risks.

Meeting Project Timelines

Tight deadlines are common in the construction industry, often placing pressure on fabrication timelines. To ensure timely delivery, effective project management techniques should be utilized, including Gantt charts and project tracking software. Clear communication between all stakeholders is essential to address potential delays proactively.

Skill Shortages in the Workforce

The structural steel fabrication industry faces a notable shortage of skilled labor. To combat this challenge, companies can invest in training programs, apprenticeships, and partnerships with technical schools. Cultivating a skilled workforce ensures that companies can maintain quality and efficiency in their fabrication processes.

Future Trends in Structural Steel Fabrication

Advancements in Technology

The future of structural steel fabrication is set to be transformed by technology. Innovations such as automation, robotics, and artificial intelligence are streamlining processes, resulting in increased efficiency and precision. Digital twin technology enables real-time simulations, allowing fabricators to optimize designs before construction begins.

Green Fabrication Practices

Sustainability is becoming increasingly important in manufacturing, and structural steel fabrication is no exception. Techniques like recycling scrap metal, using eco-friendly coatings, and minimizing waste during production contribute to more environmentally friendly practices. Implementing green methodologies not only helps the environment but can also enhance a company’s reputation.

Market Growth Predictions

As urbanization and infrastructure development continue, the market for structural steel fabrication is projected to experience significant growth. This anticipated expansion is fueled by increasing investments in construction, infrastructure, and industrial projects worldwide. Adapting to market demands and staying ahead of trends will be vital for companies in the competitive landscape of structural steel fabrication.

FAQs

What is structural steel fabrication?

Structural steel fabrication is the process of turning raw steel into finished structural components through cutting, bending, welding, and assembling various materials.

What are common cutting techniques used in fabrication?

Common cutting techniques include laser cutting, plasma cutting, waterjet cutting, and band sawing, each serving specific applications in a project.

Why is quality control important in fabrication?

Quality control ensures that fabricated steel meets safety standards and performs as intended, preventing structural failures and costly reworks.

What challenges do fabricators face with material costs?

Material cost fluctuations due to market dynamics can impact budgets. Strategic procurement and alternative sourcing can mitigate these challenges.

How can technology improve fabrication processes?

Technology enhances fabrication by increasing efficiency through automation, improving precision with advanced tools, and optimizing designs with digital simulations.